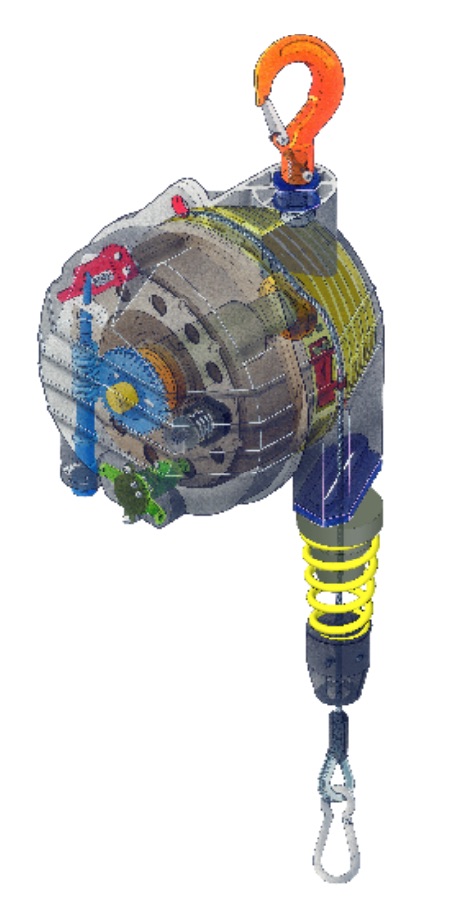

Tecna Spring Balancers

GENERAL INFORMATION

Tecna spring balancers are a solution to applications which require a tool to be positioned with minimal manual effort.

TECNA S.p.A. produces and distributes a complete range of balancers having a capacity from 0,2 up to 180 kg and an available wire stroke up to 3 meters. As a manufacturer, TECNA realizes special as well as customised versions upon demand.

The TECNA balancer is an essential device to eliminate the operator’s labor, to increase productivity by cutting down idle times and to improve the work quality. Furthermore, the use of the TECNA balancers reduces hoses and cables wear and avoid eventual damages to both people and tools.

The ergonomic structure of the TECNA balancer has been designed for facilitating each use operation, ranging from movement easiness to body robustness, from simple use to lifting power.

The following model numbers and their capacities are some of the most common, though other features and applications exist.

| Model Number | Capacity (lbsf) | Capacity (kg) | stroke (mm) | stroke (inch) | stroke (ft) |

| 9311 | 1-2 | 0.4-1 | 1600 | 63.0 | 5.2 |

| 9312 | 2-4 | 1-2 | 1600 | 63.0 | 5.2 |

| 9313 | 4-6 | 2-3 | 1600 | 63.0 | 5.2 |

| 9323 | 13-17 | 6-8 | 2000 | 78.7 | 6.6 |

| 9337 | 8-13 | 4-6 | 2500 | 98.4 | 8.2 |

| 9338 | 13-17 | 6-8 | 2500 | 98.4 | 8.2 |

| 9339 | 17-33 | 8-10 | 2500 | 98.4 | 8.2 |

| 9340 | 22-30 | 10-14 | 2500 | 98.4 | 8.2 |

| 9361B | 22-33 | 10-15 | 2000 | 78.7 | 6.6 |

| 9362B | 33-44 | 15-20 | 2000 | 78.7 | 6.6 |

| 9363B | 44-55 | 20-25 | 2000 | 78.7 | 6.6 |

| 9364B | 55-66 | 25-30 | 2000 | 78.7 | 6.6 |

| 9365B | 66-77 | 30-35 | 2000 | 78.7 | 6.6 |

| 9366BR | 77-99 | 35-45 | 2000 | 78.7 | 6.6 |

| 9367BR | 99-121 | 45-55 | 2000 | 78.7 | 6.6 |

| 9368BR | 121-143 | 55-65 | 2000 | 78.7 | 6.6 |

| 9369BR | 143-165 | 65-75 | 2000 | 78.7 | 6.6 |

| 9370BR | 165-198 | 75-90 | 2000 | 78.7 | 6.6 |

| 9371BR | 198-231 | 90-105 | 2000 | 78.7 | 6.6 |

| 9422BR | 220-253 | 100-115 | 2500 | 98.4 | 8.2 |

Note:

B= Locking-unlocking device with control from the floor

R= Rotary insulated hook

The application of the TECNA balancer is absolutely versatile: it may be used for bench or assembly line works and it may be suitably applied to small tools, industrial suspended welders and multiple screw drivers, etc.

The balancers are produced in conformity with the DIN 15112 directive and thanks to their high structural technology and their compliance with the laws in force, they are BG certified by the relevant German Institute for their safe use in the working environment. The a new balancers line ATEX certified expands the range suitable to be installed in potentially explosive areas composed by flammable gases or combustible dusts.

Pricing (USD), depending on options (*pricing subject to change, freight not included, please inquire for current pricing)