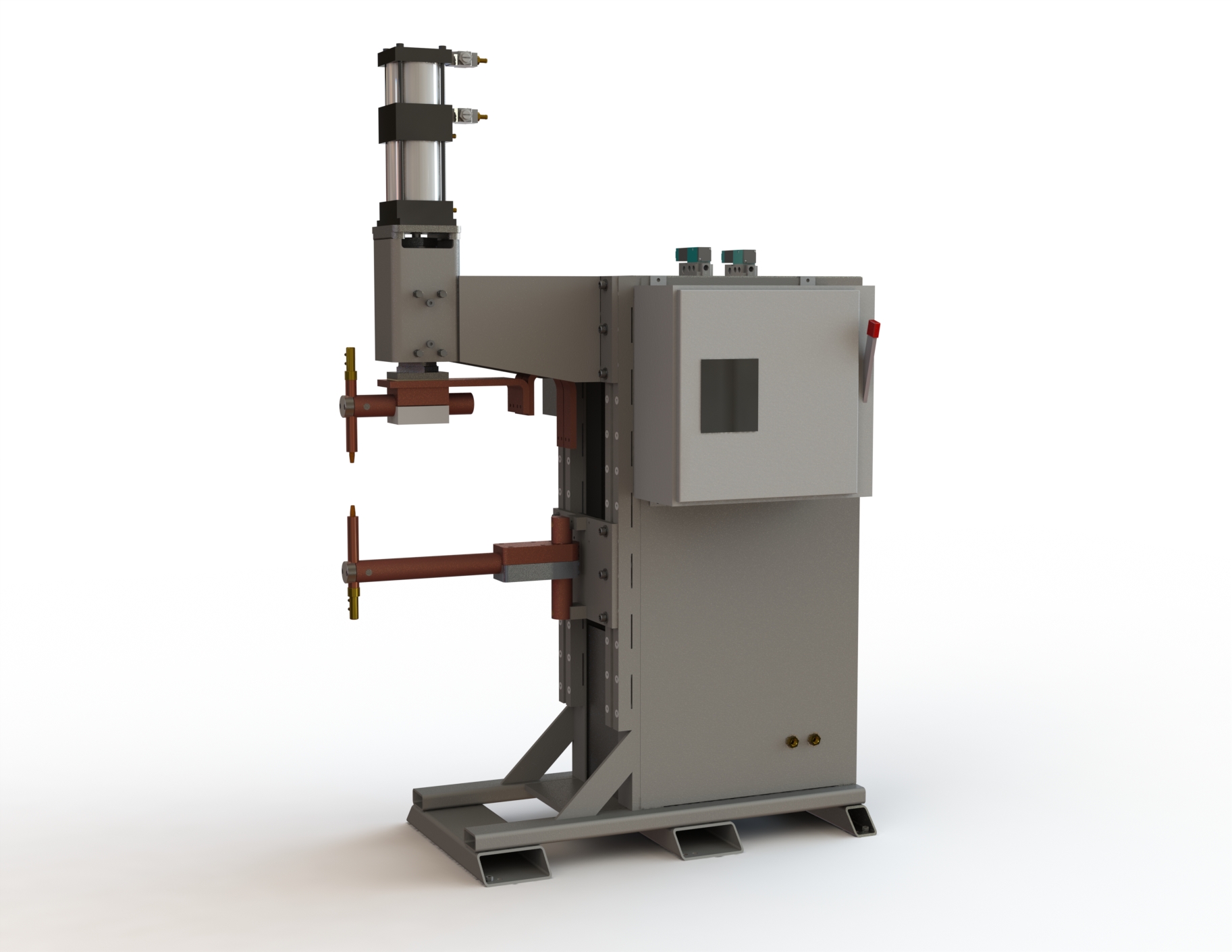

PressRite Press Spot Welders

General Information

Press style welders are the most versatile type of resistance welder. It’s the workhorse of the industry.

Press Spot welders differ from Rocker Arm welders in that the upper ram comes down in a linear fashion. With a Rocker Arm style welder, the welding electrodes effectively rotate into place. A Press Spot is ideally suited for fasteners and studs, because of this linearly descending action.

Some instances where a Press Spot welder excels:

- Welding studs or weld nuts

- Welding in tight spaces, with a round lower arm similar to a Rocker Arm

- Higher electrode force applications (compared to a rocker arm)

- Projection welding (for heavier projection welding, see Projection Welders)

- Using special tooling to fixture a part

- Frequent tooling change-overs are necessary

Spot Weld, Inc. offers three sizes of press spot welders, to optimize size costs.

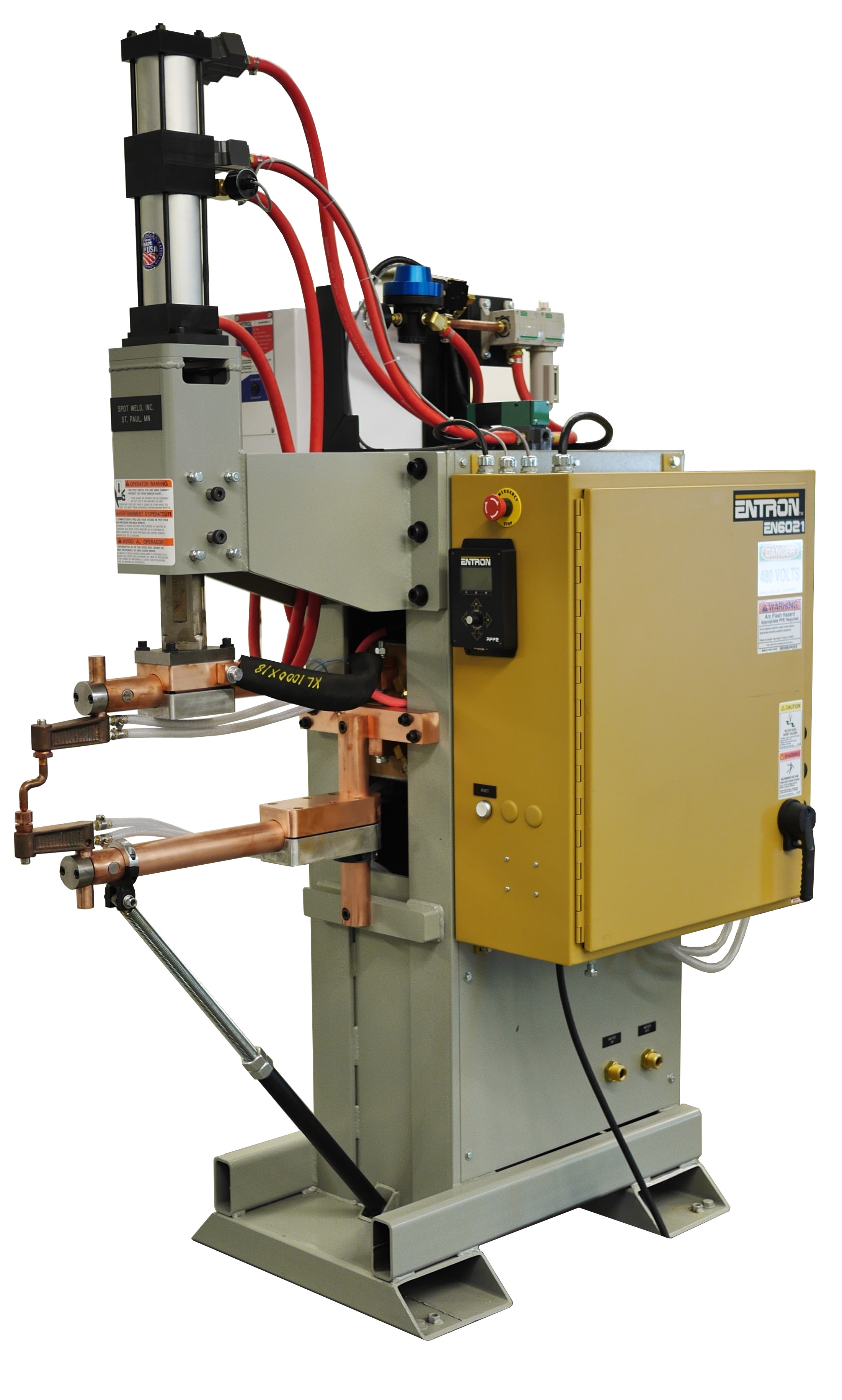

The S3 is an extra-duty press, RWMA size “3”.

- 24″ standard throat depth (can be ordered from 12” – 36”)

- 150KVA standard with 31kA max short circuit amperage; (can be ordered with 150-250KVA, we can install any transformer to suit)

- 8″ (102mm) bore air cylinder, generating 5000lbsf @ 100PSI (2220daN @ 7bar)

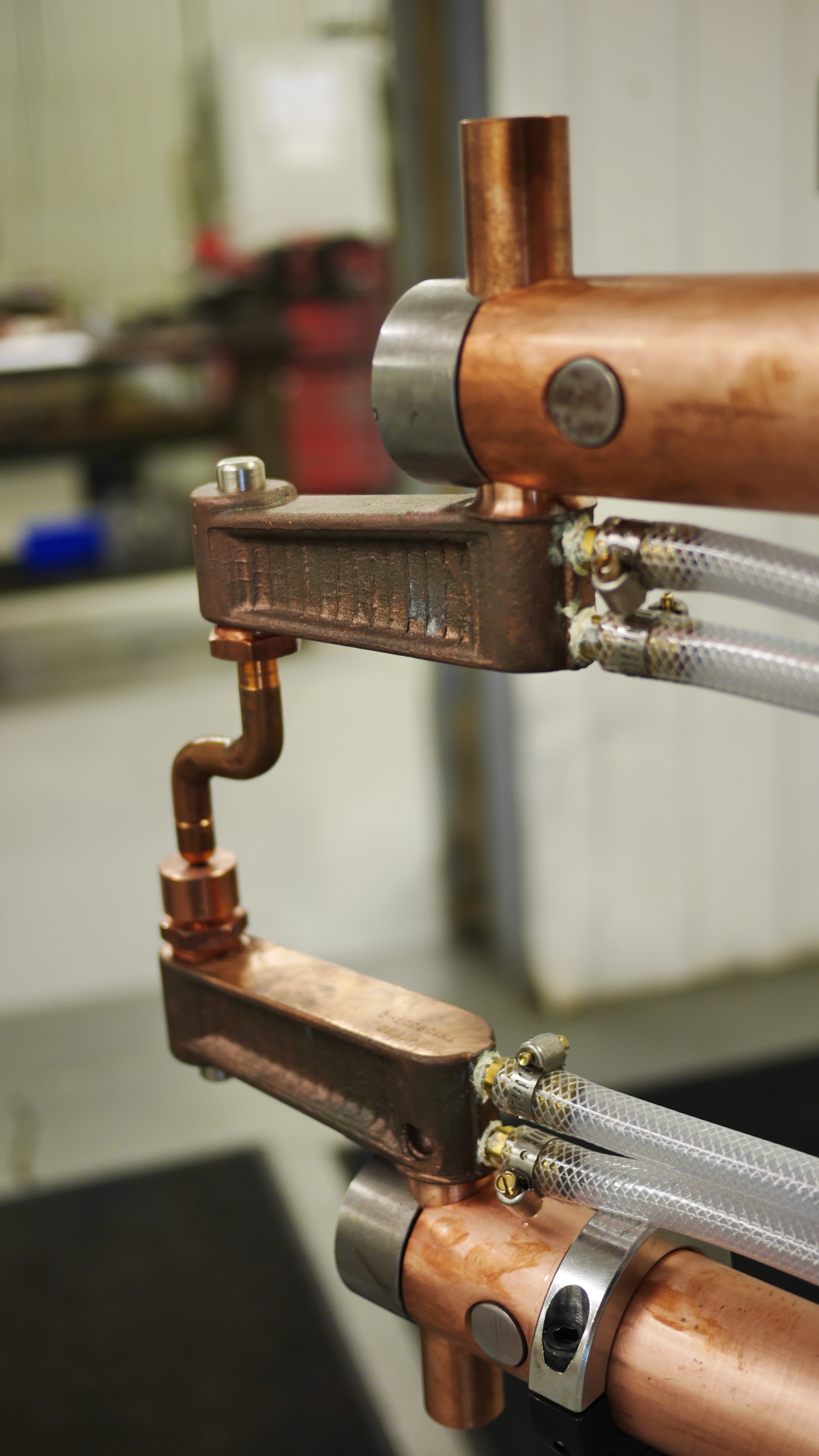

- CNC machined, 99.99% pure copper ø2-1/2” diameter upper arm, ø3-1/2” lower arm

- 5RW standard 1-1/2″ diameter ejector-style electrode holders

- The lower arm design has about 8” of vertical adjustment, allowing the deepest of parts to fit within the throat of the machine

- New in 2017, the whole upper ram attaches to the frame on t-slots, greatly increasing the adjustability and overall rigidity of the frame

- Robust frame design

- Lower arm mounted rigidly, prevents side-to-side movement, “clam-shell” design

- Fully adjustable knee support allows greater rigidity for heavier gages of metal, but can be easily removed for welding tubes, tanks, pipes, HVAC ducts

- Integrated hydraulic jack for adjusting lower knee height

- Robust roller bearing pillow blocks

- Fully rebuildable

- Precision air system

- Exclusive use of copper core, water cooled transformers

- All copper is a minimum 99.9% pure, or RWMA class

- Designed and build in the USA

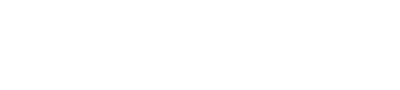

The S2 is a full size model press, RWMA size “2”.

The S2 is a full size model press, RWMA size “2”.

- 24″ standard throat depth (can be ordered from 12” – 36”)

- 75KVA standard with 21kA max short circuit amperage; (can be ordered with 30-150KVA, we can install any transformer to suit)

- 4″ (102mm) bore air cylinder, generating 1200lbsf @ 100PSI (534daN @ 7bar)

- CNC machined, 99.99% pure copper support for the upper and lower ø2-1/2” diameter arms

- 5RW standard 1-1/4″ diameter ejector-style electrode holders

- The lower arm design has about 10” of vertical adjustment, allowing the deepest of parts to fit within the throat of the machine

- New in 2017, the whole upper ram attaches to the frame on t-slots, greatly increasing the adjustability and overall rigidity of the frame

- Robust frame design

- Adjustable lower arm can swivel left & right, for even the most unusual tooling design

- Fully adjustable knee support allows greater rigidity for heavier gages of metal, but can be easily removed for welding tubes, tanks, pipes, HVAC ducts

- Robust roller bearing pillow blocks

- Fully rebuildable

- Precision air system

- Exclusive use of copper core, water cooled transformers

- All copper is a minimum 99.9% pure, or RWMA class

- Designed and build in the USA

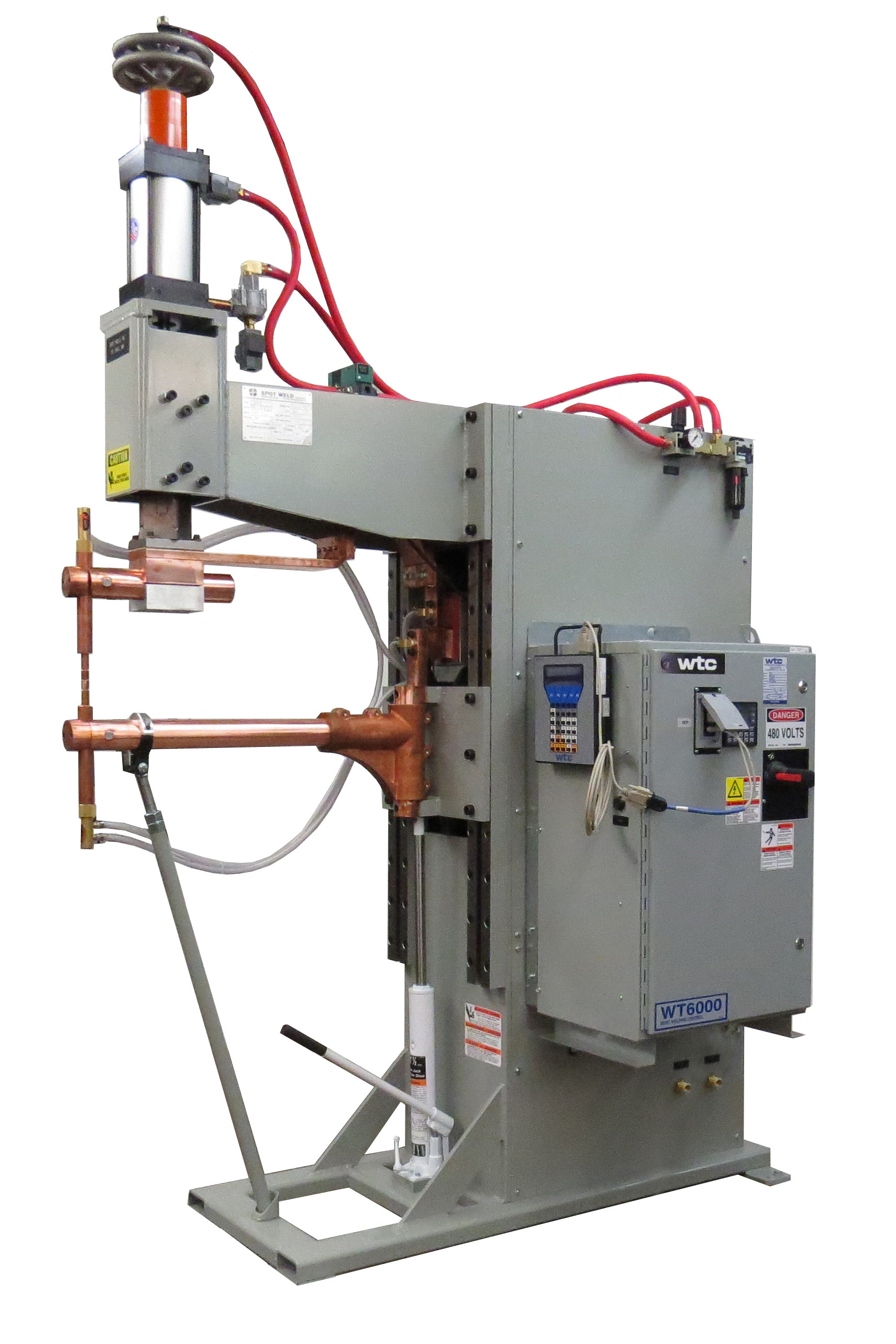

The SØ is our smaller size model, RWMA size “Ø”

The SØ is our smaller size model, RWMA size “Ø”

- 18″ Standard throat depth (can be ordered from 12” – 20”)

- 30KVA standard with 15.5kA max short circuit amperage; (can be ordered with 30-50KVA, we can install any transformer to suit)

- 3.5″ (102mm) bore air cylinder, generating 950lbsf @ 100PSI (420daN @ 7bar)

- CNC machined, 99.99% pure copper support for the upper and lower ø2” diameter arms

- 4RW standard 1″ diameter ejector-style electrode holders

- The lower arm design has about 6” of vertical adjustment, allowing the deepest of parts to fit within the throat of the machine

- Robust frame design

- Adjustable lower arm can swivel left & right, for even the most unusual tooling design

- Fully adjustable knee support allows greater rigidity for heavier gages of metal, but can be easily removed for welding tubes, tanks, pipes, HVAC ducts

- Robust roller bearing pillow blocks

- Fully rebuildable

- Precision air system

- Exclusive use of copper core, water cooled transformers

- All copper is a minimum 99.9% pure, or RWMA class

- Designed and build in the USA

Image Gallery

New for 2020, the PSØ has an updated control, new ram design, and new lower secondary mounting system. Pictured with Entron EN6001 weld control with "D" size cabinet and built-in circuit protection.

Model year 2020 PS2, light gray with new adjustable ways for lower weld arm. MFDC model shown, with WTC Gen6 control.

Single-phase AC press spot with ProCool 2 water cooler mounted on top. Spot Weld, Inc. SWI-4 weld control pictured. Caster wheels for mobility included.

MFDC 3-phase Press Spot welder. Pictured with WTC Gen6 control.

Press Spot with Unitrol SoftTouch safety system

Press Spot with Intertron 3000 MFDC inverter control

PS2 Press Spot with Entron EN6021 control, electronic air, and Unitrol SoftTouch safety device. Shown with offset electrode holders and a double-bend shank.

Tuffaloy 4" offset ejector-style electrode holders, 90-degree, with 4RW double bend shank and 4RW cap electrode on top, 7/8" diameter 4RW backup electrode on bottom.