Force Gauges

General Information

There are only three primary variables to monitor the quality of a spot weld; Current, Force, and Time. The majority of spot welding equipment does not monitor Force. Many that do monitor “force” are actually monitoring air pressure, and making a judgement to calibrate force from that reading.

Because of the importance of monitoring force, one should have at least one way to measure it. For troubleshooting purposes in a high production environment, it is common to have more than one way to measure.

These handheld force gauges are clamped between the welding electrodes directly, to learn the force where it counts.

Some common examples where a force gauge can be very useful in troubleshooting:

- the stroke of the air cylinder could be at the end of it’s travel

- the weld ram may have gotten out of alignment and is binding (or it’s otherwise not traveling smoothly because of a bad bearing/bushing, lubrication, etc)

- the air system could have a leak (air cylinder seals could be bad, bad regulator, etc)

Please note; as important as weld force is in spot welding, an accuracy of +/-3% is typically adequate. Where higher accuracy is required, the DLC gauges read +/-0.5%. If your accuracy requirements are tighter than that, please contact us for further assistance.

There are other gauges available with more sophisticated features (like “weld-thru” current reading, and more), and plenty of other force ranges. Please inquire for further details.

Here we list some of the most common force gauges.

APS Accurate Analog-Hydraulic Weld Force Gauge

Similar to the Tuffaloy Analog-Hydraulic products, but with a wider range of customization and sensor ranges, this is just a small selection of some of the common configurations available with the APS Accurate force gauges. Should you need any customization of these configurations, please contact us. We would be pleased to walk you through the options available. The part #’s in the table include the following selections:

- 2.5″ diameter gauge, with pointer (4″ diameter available)

- standard 5″ long grip (other options include Swivel Grip, Short, Long, or HD grip)

- sensor ranges from 200lbsf – 15,000lbsf

- poly pad, contoured for electrode placement (other configurations include flat, Stainless Steel, “thin”, and custom)

- NIST traceable certificates included with order (can be ordered without)

- electronic gauges available

sensor range LBS Part #

200 FG-2550-73C

300 FG-2552-73C

600 FG-2556-73C

1,000 FG-2560-73C

2,000 FG-2564-73C

3,000 FG-2566-73C

4,000 FG-2567-73C

5,000 FG-2568-73C

10,000 FG-2572-73C

15,000 FG-2574-73C

Typically priced between $450-$550 with the 2.5″ diameter pad, standard grip, poly pad, and certificate. Can be ordered in other configurations. (*pricing subject to change, freight not included, please inquire for current pricing)

(NEW!) APS Accurate Economy Digital Weld Force Gauge

APS Accurate has introduced an economy digital force gauge. It is a fixed specification, and can be ordered with or without Certification.

- 0 – 3000lbsf sensor range

- 2.5″ diameter gauge

- backlight (with on/off diaphragm switch)

- on/off diaphragm switch

- battery operated (2x “AAA”) with battery life indicator

- standard 5″ long grip

- poly pad, contoured for electrode placement

- NIST traceable certificates included with order (can be ordered without)

- Part #FG-5566-73 (no cert)

- Part #FG-5566-73CD (with cert)

Typically priced between $900 – $1100 depending on certification. Can be ordered in other configurations, please inquire. (*pricing subject to change, freight not included, please inquire for current pricing)

(NEW!) Tuffaloy Digital-Hydraulic Weld Force Gauge

DLC Series Gauges offer affordable high accuracy with large LCD display. All models have field selectable units in Lbs, Kg, Newton & KiloNewton. High Strength spring mounted load cell features 150% overload capacity, a large landing pad for electrode pinch point and requires electrode gap of only 9/16”. Full 5-digit large LCD display is environmentally sealed for rugged applications and comes standard with Peak Hold feature. +/-0.5% accuracy. NIST Traceable certification. 500ms response time. These gauges cannot be welded thru.

- 0-3000 lbs max reading

- increment every 1 lbs

- 0.57″ gap required between the electrodes

- pt# 601-3000DLC

- 0-5000 lbs max reading

- increment every 1 lbs

- 0.57″ gap required between the electrodes

- pt# 601-5000DLC

Typically priced in the $1700-$1800 range. (*pricing subject to change, freight not included, please inquire for current pricing)

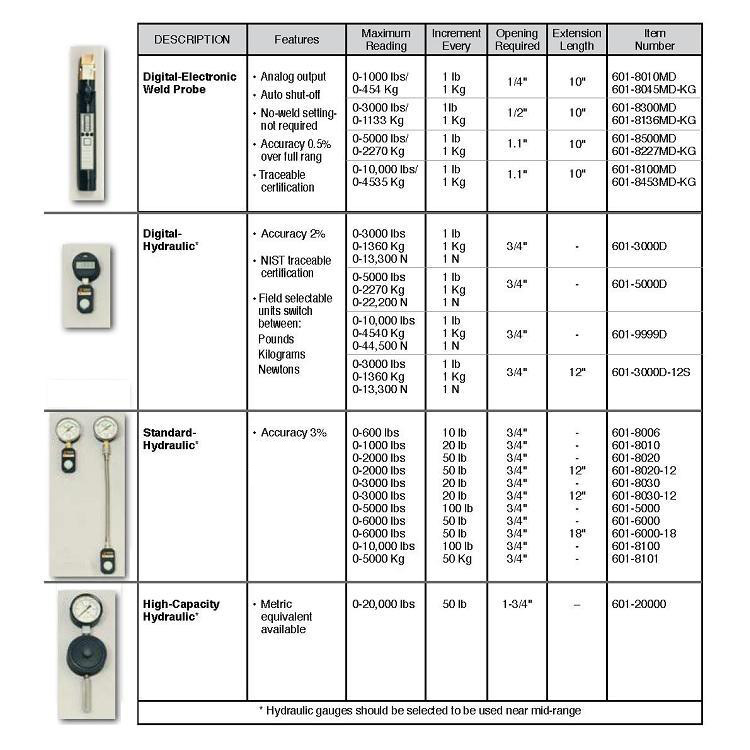

Tuffaloy Digital-Electronic Weld Force Probe

more about Tuffaloy Digital-Electronic Weld Force Probe

Note: can only be ordered to read in Imperial or Metric. The following part numbers are for Imperial (pounds [lbsf]) only. Please inquire for Metric (Kg) part numbers and pricing.

- 0-1000 lbs max reading

- increment every 1 lbs

- 0.25″ gap required between the electrodes

- pt# 601-8010MD

- 0-3000 lbs max reading

- increment every 1 lbs

- 0.25″ gap required between the electrodes

- pt# 601-8300MD

- 0-5000 lbs max reading

- increment every 1 lbs

- 0.25″ gap required between the electrodes

- pt# 601-8500MD

- 0-10,000 lbs max reading

- increment every 1 lbs

- 0.25″ gap required between the electrodes

- pt# 601-8100MD

Typically priced in the $4k-$5k range. (*pricing subject to change, freight not included, please inquire for current pricing)

Tuffaloy Analog-Hydraulic Weld Force Gauge

Analog-Hydraulic gauges are the low cost method for obtaining general force measurements. These gauges are available in a standard block style, with extensions. Sizes range from 600 pounds (lb) up to 10 tons (tn) with accuracy of 2% at the mean and 3% outside of mean for 70% of the gauge’s range. These gauges cannot be welded thru. They are not repairable.

- 0-2000 lbs max reading

- increment every 50 lbs

- 0.75″ gap required between the electrodes

- pt# 601-8020

- also available with 12″ extension, changes gauge part number to pt# 601-8020-12

- 0-3000 lbs max reading

- increment every 20 lbs

- 0.75″ gap required between the electrodes

- pt# 601-8030

- also available with 12″ extension, changes gauge part number to pt# 601-8030-12, *discontinued

- 0-5000 lbs max reading

- increment every 100 lbs

- 0.75″ gap required between the electrodes

- pt# 601-5000

- 0-10,000 lbs max reading

- increment every 100 lbs

- 0.75″ gap required between the electrodes

- pt# 601-8100

Typically priced in the $450-$550 range for the base gauge. Can be ordered with Certification, extension, and/or steel pad for additional cost. (*pricing subject to change, freight not included, please inquire for current pricing)

Tuffaloy Digital-Hydraulic Weld Force Gauge (discontinued)

more about Digital-Hydraulic Force Gauge

- 0-3000 lbs max reading

- increment every 1 lbs

- 0.75″ gap required between the electrodes

- pt# 601-3000DR, *discontinued

- also available with 12″ extension, changes gauge part number to pt# 601-3000DR-12S

- 0-5000 lbs max reading

- increment every 1 lbs

- 0.75″ gap required between the electrodes

- pt# 601-5000DR, *discontinued

- 0-10,000 lbs max reading

- increment every 1 lbs

- 0.75″ gap required between the electrodes

- pt# 601-9999DR, *discontinued

Typically priced in the $1300 range. (*pricing subject to change, freight not included, please inquire for current pricing)