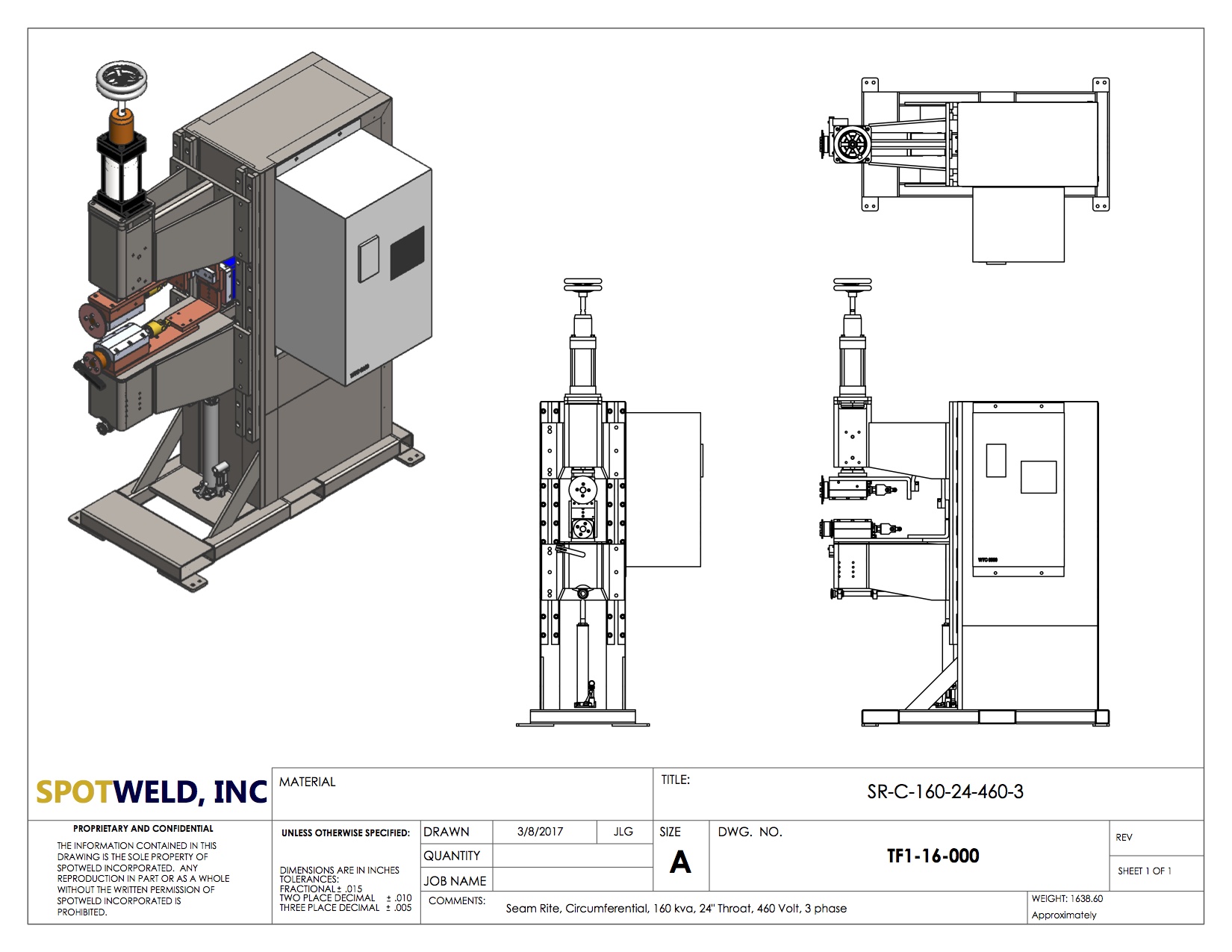

Inverters (MFDC)

GENERAL INFORMATION

An Inverter has many advantages over traditional 1-phase AC welding. Some advantages are greater welding precision, more efficient use of electricity, smaller package size, and less electrical loss due to impedance.

Like every welding technology, an Inverter (also often referred to as Mid-Frequency Direct Current [MFDC]) has it’s place. Many plants across the world have learned that an Inverter has many superior properties that make it worth the added upfront cost. Automotive plants have almost exclusively switched to Inverters because of their light weight, their quality feedback, their electrical power savings, and universal support.

Any of the Spot Weld, Inc. OEM equipment can be fit with an Inverter; from rocker arms to presses, bench tops and seam welders, and custom equipment as well. We are also a distributor for some imported machines that are equipped with Inverters.

SWI has developed three standard Inverters for contract manufacturers and job shops; especially those seeking NADCAP or other aerospace qualifications. These machines are intended to take the guessing out of the shopping experience and provide all you will ever need when you don’t yet know what that is.

PMF160

- 160KVA 1000Hz MFDC Inverter

- 230V-600V primary available, 50/60Hz, 3-phase

- 24″ (610mm) throat depth

- 2000lbsf (890daN), 5″ (127mm) bore air cylinder

- 30kA max secondary Amps at the electrodes

- SoftTouch pinch protection system

- MFDC 3-phase inverter with closed loop feedback

- Weld schedule selection via on-board PLC

- 150-Amp integrated circuit breaker

- Fixed retractable air cylinder

- Platten-ready, for custom tooling

- Adjustable lower knee

- Upper ram assembly adjustable

- Designed and build in the USA

The PMF160 can perform Commercial, Mil-spec 6858D, and AWS 17.2 Class B & C spot welds on two thicknesses of aluminum up to 0.080″ (2mm) thick.

PMF170

- 170KVA 1000Hz MFDC Inverter

- 230V-600V primary available, 50/60Hz, 3-phase

- 24″ (610mm) throat depth

- 2000lbsf (890daN), 5″ (127mm) bore air cylinder

- 44kA max secondary Amps at the electrodes

- SoftTouch pinch protection system

- MFDC 3-phase inverter with closed loop feedback

- Weld schedule selection via on-board PLC

- 250-Amp integrated circuit breaker

- Fixed retractable air cylinder

- Platten-ready, for custom tooling

- Adjustable lower knee

- Upper ram assembly adjustable

- Designed and build in the USA

The PMF170 can perform Commercial, Mil-spec 6858D, and AWS 17.2 Class B & C spot welds on two thicknesses of aluminum up to 0.125″ (3mm) thick.

PMF320

- 320KVA 1000Hz MFDC Inverter

- 230V-600V primary available, 50/60Hz, 3-phase

- 18″ (460mm) throat depth

- 8000lbsf (3560daN), 10″ (254mm) diaphragm-style Fast Follow Up air system

- 55kA max secondary Amps at the electrodes

- SoftTouch pinch protection system

- MFDC 3-phase inverter with closed loop feedback

- Weld schedule selection via on-board PLC

- 400-Amp integrated circuit breaker

- Fixed retractable air cylinder

- Platten-ready, for custom tooling

- Adjustable lower knee

- Upper ram assembly adjustable

- Designed and build in the USA

The PMF320 has a diaphragm air system and can perform commercial, Mil-spec 6858D, and AWS 17.2 Class A, B, & C welds. Please inquire for more detailed information.