Electrode Configurer – Determine Taper

Electrode Configurer – Determine Taper

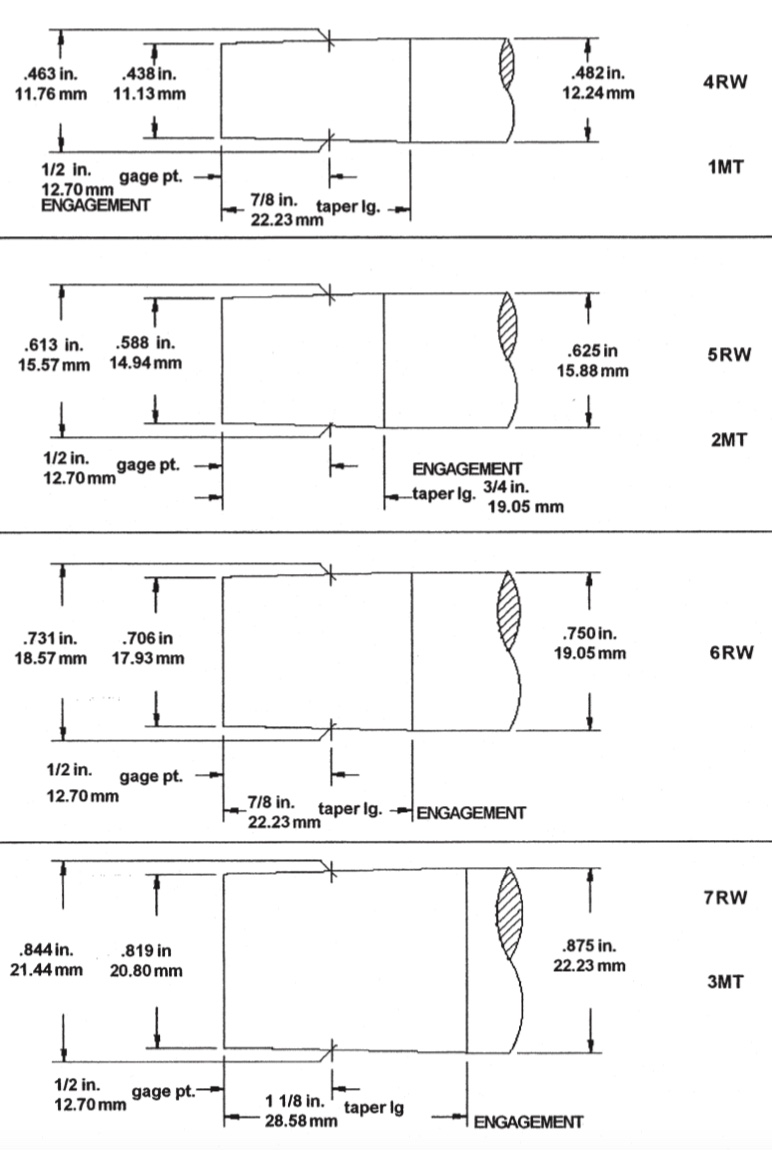

Often the most confusing and problematic thing about selecting electrodes is determining the Taper size. If your machine is from a North American manufacturer, or if it has been modified to comply with North American standards (which is easy and common), then you have one of four taper sizes. If you skip this step, you can’t select an electrode!

You need to figure out which one of these Tapers fits in your electrode holder. Go to your machine and measure the hole in the end of your electrode holder with a caliper. It’s also sometimes possible to measure the diameter of the electrode that is in the electrode holder.

Use the chart above to determine your taper. Remember, if you use a caliper, you’re measuring a taper, so the deeper you push the caliper into the hole, the smaller the measurement will get.

Remember, the most common Tapers are 4RW and 5RW.

If your electrode holder taper measures between about 0.46″ and 0.48″, then you likely have a 4RW Taper.

If your electrode holder taper measures between about 0.61″ and 0.63″, then you likely have a 5RW Taper.

If you measure tapers greater than that, please see table above to match with 6-7RW.

Now that you know your Taper size, please continue to the Electrode Shape.

Back Next to Electrode Shape